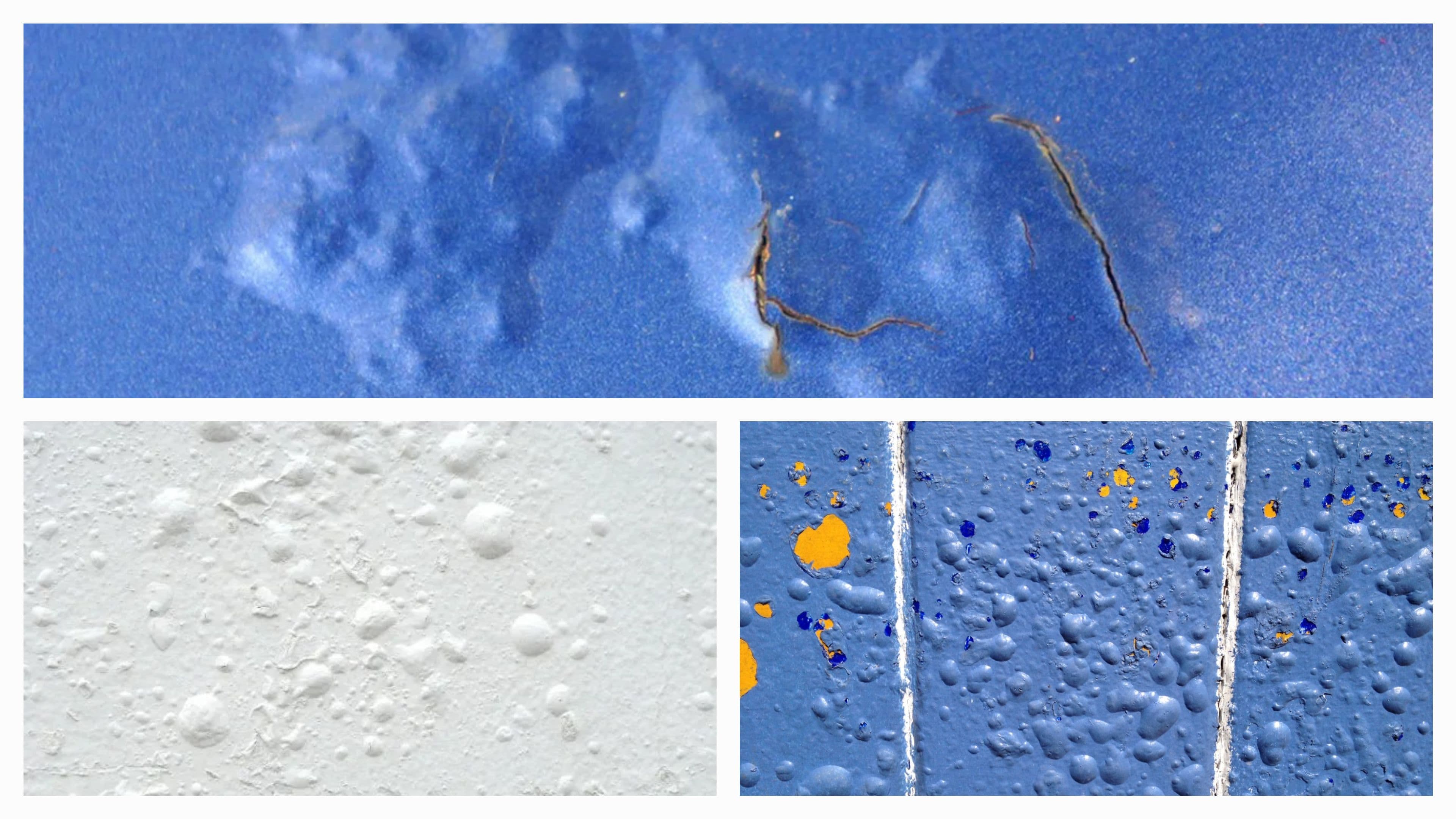

1. Probable Cause / Reason:

• Presence of soluble salts, pigments, or corrosion products beneath the coating.

• Retained solvents in the coating film or from previous cargo exposure.

• Cathodic disbonding and thermal stresses causing coating lift-off.

• Cold-wall effects and compressive stresses creating localized blistering.

2. Correction / Repair:

• Identify and remove all blistered and poorly adhered coating areas.

• Thoroughly clean and prepare the surface, ensuring no soluble salts remain.

• Apply an appropriate primer and topcoat after confirming surface readiness.

• Ensure correct application techniques to avoid solvent entrapment.

3. Corrective Action / Prevention:

• Perform surface preparation tests for soluble salts and contaminants.

• Apply coating systems suited to the operating environment and conditions.

• Follow proper drying times, environmental controls, and product guidelines.

BG GROUP OF PAINT AND COATING CONSULTANT

Email: support@bgcoating.com / inquiry.bggroup@gmail.com

Website: https://bgcoating.com

LinkedIn: https://www.linkedin.com/company/bggroupofpaintandcoatingconsultant/

Google My Business: https://maps.app.goo.gl/pUMmXu4D5tPhpnbh9

Booking Appointment: https://forms.gle/YaYPVNUT6ai3Ucuj9