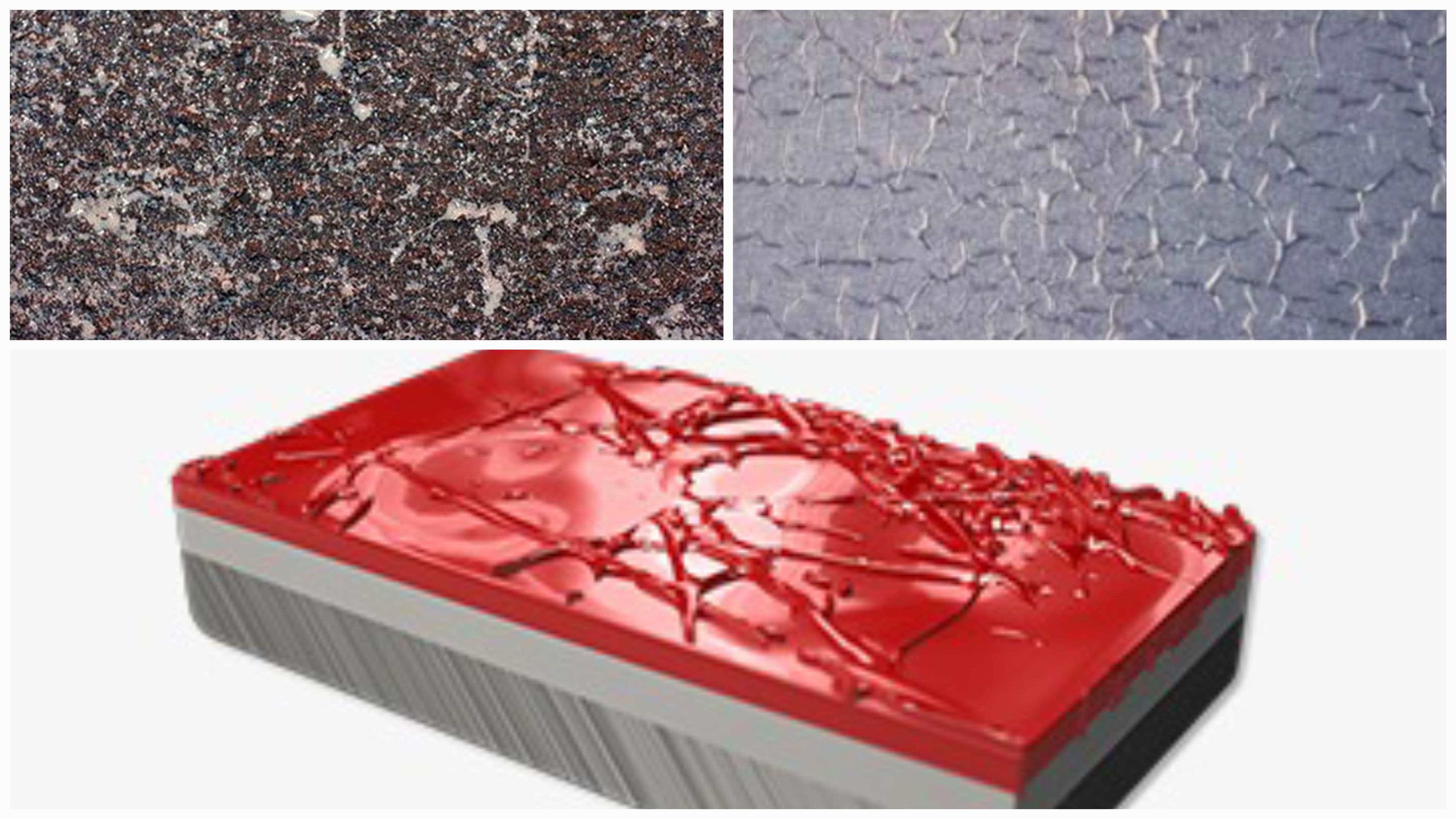

1. Probable Cause / Reason:

• High viscosity in certain polymer solutions, leading to poor atomization.

• Occurs with chlorinated rubber coatings at almost any viscosity level.

• Improper spraying conditions causing the formation of fine filaments instead of droplets.

• Use of inappropriate solvent blends that fail to reduce viscosity properly.

2. Correction:

• Reduce the viscosity of the coating to improve atomization.

• Select a more appropriate solvent blend to achieve optimal spraying consistency.

• Adjust spraying conditions, such as air pressure and nozzle size, to prevent fine filaments.

• Ensure that the correct spray equipment is used for the specific coating type.

3. Corrective Action / Prevention:

• Thin the coating to the proper viscosity to enhance atomization.

• Reapply the coating with improved spraying parameters.

• Regularly check and adjust the solvent blend and spray settings for optimal results.

BG GROUP OF PAINT AND COATING CONSULTANT

Email: support@bgcoating.com / inquiry.bggroup@gmail.com

Website: https://bgcoating.com

LinkedIn: https://www.linkedin.com/company/bggroupofpaintandcoatingconsultant/

Google My Business: https://maps.app.goo.gl/pUMmXu4D5tPhpnbh9

Booking Appointment: https://forms.gle/YaYPVNUT6ai3Ucuj9