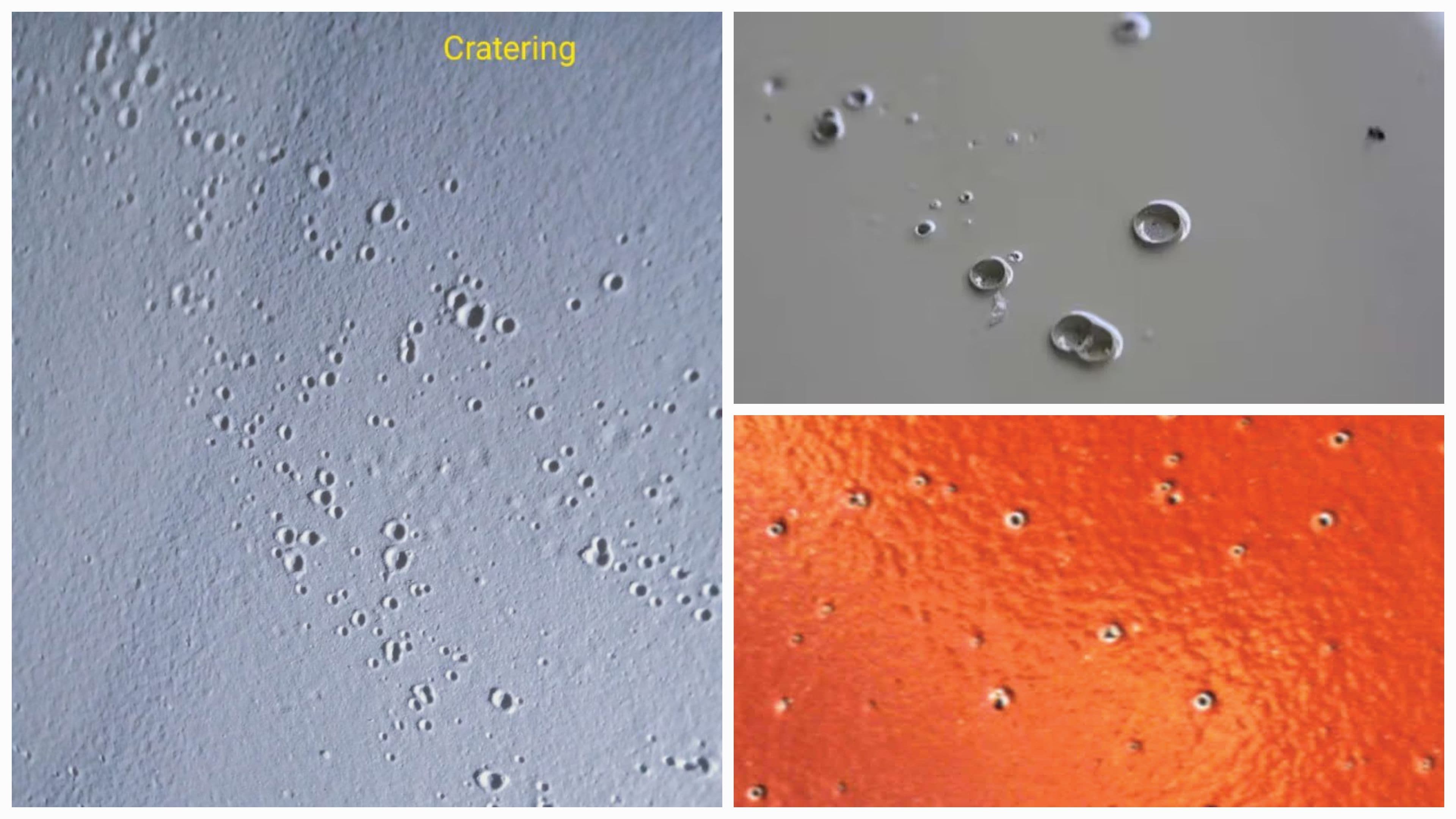

1. Probable Cause / Reason:

• Trapped air or solvent bubbles that burst, creating small craters.

• Insufficient time for the coating to flow into a uniform film.

• Air entrainment during mixing or spraying.

• Over-thinning or incorrect solvent blend can also cause poor flow.

2. Correction:

• Improve spraying technique to reduce air entrapment.

• Apply a mist coat before the main coat to allow better leveling.

• Avoid excessive thinning or use the recommended thinner for optimal flow.

• Ensure proper drying conditions to allow the coating to settle evenly.

3. Corrective Action / Prevention:

• Remove the affected area and reapply the coating with improved technique.

• Ensure proper mixing and spraying to minimize air bubbles.

• Monitor and adjust application speed and pressure for smoother coverage.

BG GROUP OF PAINT AND COATING CONSULTANT

Email: support@bgcoating.com / inquiry.bggroup@gmail.com

Website: https://bgcoating.com

LinkedIn: https://www.linkedin.com/company/bggroupofpaintandcoatingconsultant/

Google My Business: https://maps.app.goo.gl/pUMmXu4D5tPhpnbh9

Booking Appointment: https://forms.gle/YaYPVNUT6ai3Ucuj9